ATI “SUPER DAMPER” HARMONIC BALANCER – DODGE / JEEP 3.7L & 4.7L +HO

$413.99

ATI SUPER DAMPER DETAILS ATI SUPERIOR DESIGN WHAT IS A BALANCER? CHOSE THE CORRECT BELT SIZECHRYSLER DAMPER CHART

The patented ATI Super Damper is the only damper designed exclusively for low to high rpm performance engines. FINALLY available to the 3.7L & 4.7L / HO community! Air Ram Performance worked along with ATI to bring you the ATI Superdamper to both the Chrysler 4.7L and 3.7L engines with the optional 25% under-drive pulley which is good for a solid 10RWHP gain along with unmatched engine protection!

When ordering, please keep in mind that there are two options to chose from. There is the OEM size pulley and the 25% under-drive pulley options.

** NOTES ** – The 7.07″ Damper is available however should only be considered for applications OVER 550HP. The larger 7.07″ damper weighs 6.25lbs compared to the smaller 6.25″ damper which only weighs 3.9lbs! The 6.25″ Damper will provide all the protection your engine needs while being as light weight as possible contributing to quicker revs. Most applications will bennifit with the use of the 6.25″ damper and is what we keep in stock on the shelf. If you require the 7.07″ damper, we can source it for you directly from the manufacture and can take 1-2 weeks to ship depending on availability and or production times.

The proven elastomer design is actually two dampers in one: a 4″ diameter and a 6.25″ / 7.00″ (depending on pulley option) diameter damper contained in two shells that bolt to the crank hub. The inner and outer shells are available in steel and in aluminum to contain the steel inertia weight. The inertia weight has eight computer machined grooves to retain the proper durometer O-rings (dyno tested for each application), and installed at ATI. O-ring life has been tested to over two million cycles in Winston Cup competition and 10 years in drag racing engines. The unit is rebuild able to new specifications by installing new O-rings. Extensive dyno and on-track testing has proven the Super Damper far superior to all other designs, especially on engines that turn over 6000 rpm, and is used on nearly 100 percent of all Winston Cup engines. Shells are black zinc chromate finished, with computer controlled, laser engraved 360 timing marks. Exceeds SFI 18.1 specs.

* Eliminates torsional crankshaft vibrations

* Exceeds SFI 18.1 specs

* Black zinc chromate finished

* OEM equipment on 392 Mopar Crate Engines

* Tunable, rebuild-able, and extremely efficient at ALL RPM

* Laser engraved 360 timing marks

Under drive pulley systems increase engine horsepower by reducing the amount of power required to drive external accessories. For example, the alternator, power steering, water pump and air conditioner all rob horsepower from the engine. By replacing factory-sized crank and accessory drive pulleys with a resized pulley, the accessories are slowed, resulting in more horsepower available to drive the rear wheels.

For those who dont know what a balancer does or why its important to step up to a performance balancer here is some incite I put together found on the web.The main function of the engine system is to convert gasoline or diesel if its a diesel engine into motion so that you car can move. And this is done by burning it inside the engine which is known as the internal combustion engine. The engine system is composed of various parts and damage to any of these parts will greatly affect the overall performance of the engine that is why some materials and devices are attached to it to prevent this problem. One of which is the harmonic balancer.

The harmonic balancer, which is also known as a harmonic damper, is essential to the longevity of an engine since it prevents crankshaft failure. It is usually mounted at the front end of the crankshaft in order to absorb and dissipate the majority of the vibration energy. It consists of the hub, an outer weight ring, and a sandwiched layer of flexible rubber. It is the rubber that absorbs the energy of the vibrating crankshaft in the form of heat, damping the amount of vibration to within safe limits.

The crankshaft is the part of the engine that converts the up and down motion of the pistons and connecting rods during the combustion cycle into rotary motion that spins the transmission and the vehicles drive wheels. Every time a cylinder fires, the force twists the crankshaft. When the cylinder stops firing the force ceases to act and the crankshaft starts to return to the untwisted position. However, the crankshaft will overshoot and begin to twist in the opposite direction, and then back again. Eventually the crankshaft will experience torsional vibration which can cause it to fail after some time.

In order to keep this problem from occurring, installing a harmonic balancer for your vehicle is necessary and every 4 stroke engine made will have some form of a harmonic balancer installed. Otherwise, engines would not last much further than a trip to the end of the street and back.

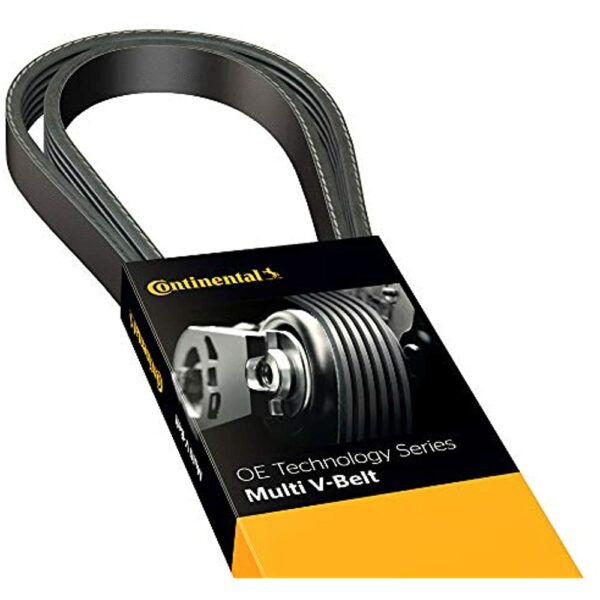

Over the years Chrysler has made some changes to the accessories configuration and belt routing. This means that not all 4.7L and 3.7L applications will use the same belt lengths. In order to insure you purchase the correct length belt, it is important that you do some homework on the belt length for your specific application. We have listed 2 belts that will fit most applications, we will add more to the list as customers report the belt lengths /applications to us.

We have listed 2 belts that have been verified on Dodge Rams. If you know the belt length you need for your application, please let us know and we will add it to the product page.

The 25% under-drive pulley will require a belt that is between 2.75″ & 3.00″ shorter than the recommended factory belt. Simply look up your belt size and belt length, then subtract 2.75″ – 3.00″ from that and you will have the correct length belt to run with your 25% under-drive pulley. Simply order the correct belt length that has the same rib count/width (6-rib/20.96width) as factory however shorter for the UD pulley. If you send us the information, we will add the belt to the product page for one stop shopping

25% UNDERDRIVE PULLEY – RECOMMENDED BELT SIZE:

Most 1999-2007 3.7L & 4.7L engines – 4060855

- Belt Length (in.): 85.50 in.

- Belt Length (mm): 2171.70mm

- Number of Belt Ribs: 6

- Belt Width (in.): 0.830 in.

- Belt Width (mm): 20.96mm

OEM PULLEY RECOMMENDED BELT SIZE:

Most 1999-2007 3.7L & 4.7L engines – 4060882

- Belt Length (in.): 88.25 in.

- Belt Length (mm): 2241.55mm

- Number of Belt Ribs: 6

- Belt Width (in.): 0.830 in.

- Belt Width (mm): 20.96mm

Chrysler Serpentine Dampers

| YEARS | ENGINE | DAMPER PART # |

OUTER DIAMETER |

AVG WEIGHT LESS HUB |

SHELL MATERIAL |

SHELL # | RIBS | HUB # | HUB MATERIAL |

| 4.7 AND SOME 3.7 RAM, DAKOTA, GRAND CHEROKEE W/BOLT-ON PULLEY OEM (PT# 916236) & 25% UD (PT# 916237) |

918429 | 7.07″ OEM | 6.25 LBS | ALUM | 918850 | 6 | 916311 | STEEL | |

| 918428 | 6.32″ 25% UD | 3.9 LBS | ALUM | 917070 | 6 | 916311 | STEEL | ||

| ’05 -’10 NON-VVT |

6.1 L / CRATE 392 & 426 HEMI STOCK |

918432 | 6.78″ 5% OD | 4.5 LBS | ALUM | 917071-55 | 6 | 916652 | STEEL |

| 918437 | 7.48″ 17% OD | – | ALUM | 917073 | 6 | 916652 | STEEL | ||

| 918438 | 5.67″ 13% UD | 3.6 LBS | ALUM | – | 6 | 916241 | STEEL | ||

| ’11-’20 VVT |

5.7L & 6.4L HEMI CHARGER, CHALLENGER, 300C,GRAND CHEROKEE, COMMANDER, DURANGO |

918487 | 5.67″ 15% UD | – | ALUM | – | 6 | 916241 | STEEL |

| 918459 | 6.78″ 6% OD | – | ALUM | 917071 | 6 | 916541 | STEEL | ||

| 918486 | 7.48″ 18% OD |

–

|

ALUM | 917073 | 6 | 916541 | STEEL | ||

| ’09 – ’10 VVT |

5.7L HEMI CHARGER, CHALLENGER, 300C,GRAND CHEROKEE, DURANGO, ASPEN | 918446 | 7.48″ 18% OD |

–

|

ALUM | 917073 | 6 | 916246 | STEEL |

| 918447 | 5.67″ 15% UD |

3.6 LBS

|

ALUM | – | 6 | 916245 | STEEL | ||

| ’05 -’08 NON-VVT |

300, MAGNUM, GRAND CHEROKEE, CHARGER, COMMANDER | 918436 | 7.48″ 10% OD | 4.5 LBS | ALUM | 917073 | 6 | 916247 | STEEL |

| 918435 | 6.78″ 2% UD |

–

|

ALUM | 917071 | 6 | 916247 | STEEL | ||

| ’03 -’08 NON-VVT |

5.7L HEMI TRUCK LENGTH DURANGO, ASPEN | 918434 | 7.48″ 4% OD |

–

|

ALUM | 917044 | 8 | 916248 | STEEL |

| 918433 | 6.78″ 5% UD | 4.5 LBS | ALUM | 917075 | 8 | 916248 | STEEL | ||

| 918439 | 5.93″ 15% UD | 7.55 LBS | ALUM | – | 7 | 916242 | STEEL | ||

| ’09-’20 VVT |

5.7L & 6.4L HEMI TRUCK, DURANGO |

7.48″ 18% OD | 9 LBS | ALUM | 917044 | 8 | 916248 | STEEL | |

| 5.7L HEMI TRUCK LENGTH DURANGO | 918453 | 6.7″ 6% OD | 4.5 LBS | ALUM | 917075 | 8 | 916238 | STEEL | |

| 918454 | 7.074″ 15% UD |

–

|

ALUM | 917020 | 6 | 916239 | STEEL | ||

| ’15+ VVT |

6.2L SUPERCHARGED V8 HEMI HELLCAT, ’18 DEMON CHALLENGER, CHARGER, TRACKHAWK |

918483 | 8.18″ OEM | – | ALUM | 918483S | 10 & 6 | 916278 | STEEL |

| 918485 | 8.90″ 10% OD | – | ALUM | 918485S | 10 & 6 | 916278 | STEEL | ||

| ’00 – ’10 | NEON SRT-4 / PT CRUISER (’00-’10) DOUBLE 4 RIB OUTER SHELL | 917469 | 6.78″ 7% OD |

4.5 LBS

|

ALUM | – | 4 | 916422 | STEEL |

|

|

| CHOOSE BASIC OPTIONS | 6.32" SMALL DAMPER – 918428 – 3.9 LBS – up to 550HP, 7.07" LARGE DAMPER – 918429 – 6.25 LBS – 550HP+ |

|---|---|

| CHOOSE PULLEY SIZE | 25% UNDER-DRIVE PULLEY, OEM SIZED PULLEY |

| MAKE | MODEL | YEAR |

|---|---|---|

| MAKE | MODEL | YEAR |

| DODGE | DAKOTA | 2000 - 2011 |

| DODGE | DAKOTA | 2004 - 2011 |

| DODGE | DURANGO | 2000 - 2003 |

| DODGE | DURANGO | 2004 - 2007 |

| DODGE | DURANGO | 2004 - 2009 |

| DODGE | DURANGO | 2008 - 2013 |

| DODGE | RAM 1500 | 2002 - 2007 |

| DODGE | RAM 1500 | 2002 - 2008 |

| DODGE | RAM 1500 | 2008 - 2013 |

| DODGE | RAM 1500 | 2009 - 2012 |

| JEEP | CHEROKEE | 2002 (KJ) |

| JEEP | CHEROKEE | 2003 (KJ) |

| JEEP | CHEROKEE | 2004 (KJ) |

| JEEP | CHEROKEE | 2005 (KJ) |

| JEEP | CHEROKEE | 2006 (KJ) |

| JEEP | CHEROKEE | 2007 (KJ) |

| JEEP | CHEROKEE | 2008 (KK) |

| JEEP | CHEROKEE | 2009 (KK) |

| JEEP | CHEROKEE | 2010 (KK) |

| JEEP | CHEROKEE | 2011 (KK) |

| JEEP | CHEROKEE | 2012 (KK) |

| JEEP | CHEROKEE | 2013 (KK) |

| JEEP | COMMANDER | 2005 (XK) |

| JEEP | COMMANDER | 2005 (XK) |

| JEEP | COMMANDER | 2006 (XK) |

| JEEP | COMMANDER | 2006 (XK) |

| JEEP | COMMANDER | 2007 (XK) |

| JEEP | COMMANDER | 2007 (XK) |

| JEEP | COMMANDER | 2008 (XK) |

| JEEP | COMMANDER | 2008 (XK) |

| JEEP | COMMANDER | 2009 (XK) |

| JEEP | COMMANDER | 2009 (XK) |

| JEEP | COMMANDER | 2010 (XK) |

| JEEP | GRAND CHEROKEE | 1999 (WJ) |

| JEEP | GRAND CHEROKEE | 2000 (WJ) |

| JEEP | GRAND CHEROKEE | 2001 (WJ) |

| JEEP | GRAND CHEROKEE | 2002 (WJ) |

| JEEP | GRAND CHEROKEE | 2002 (WJ) |

| JEEP | GRAND CHEROKEE | 2003 (WJ) |

| JEEP | GRAND CHEROKEE | 2003 (WJ) |

| JEEP | GRAND CHEROKEE | 2004 (WJ) |

| JEEP | GRAND CHEROKEE | 2004 (WJ) |

| JEEP | GRAND CHEROKEE | 2005 (WK) |

| JEEP | GRAND CHEROKEE | 2005 (WK) |

| JEEP | GRAND CHEROKEE | 2006 (WK) |

| JEEP | GRAND CHEROKEE | 2006 (WK) |

| JEEP | GRAND CHEROKEE | 2007 (WK) |

| JEEP | GRAND CHEROKEE | 2007 (WK) |

| JEEP | GRAND CHEROKEE | 2008 (WK) |

| JEEP | GRAND CHEROKEE | 2008 (WK) |

| JEEP | GRAND CHEROKEE | 2009 (WK) |

| JEEP | GRAND CHEROKEE | 2009 (WK) |

| JEEP | GRAND CHEROKEE | 2010 (WK) |

| JEEP | LIBERTY | 2003 (KJ) |

| JEEP | LIBERTY | 2004 (KJ) |

| JEEP | LIBERTY | 2005 (KJ) |

| JEEP | LIBERTY | 2006 (KJ) |

| JEEP | LIBERTY | 2007 (KJ) |

| JEEP | LIBERTY | 2008 (KK) |

| JEEP | LIBERTY | 2009 (KK) |

| JEEP | LIBERTY | 2010 (KK) |

| JEEP | LIBERTY | 2011 (KK) |

| JEEP | LIBERTY | 2012 (KK) |

You May Also Like:

Related products

-

VALVE SPRINGS, LOCKS & RETAINERS

COMP CAMS Valve Springs – BEEHIVE – (4.7L) – 26125-16 “275lbs”

$287.99 Add to cart -

ENGINES AND COMPONENTS

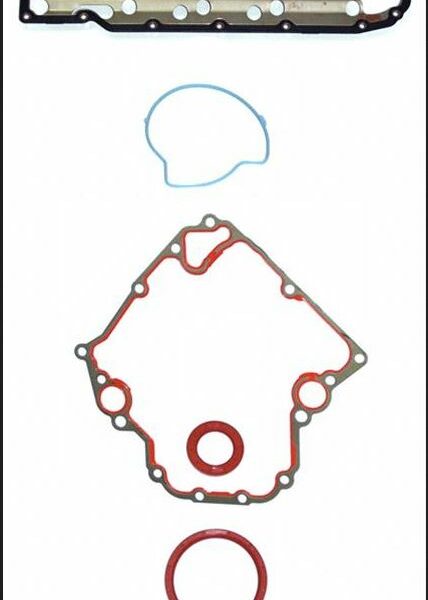

TIMING COVER / WATER PUMP / OIL PAN / CRANK SEALS – FELPRO – 4.7L

$165.38 Add to cart