ARP HEAD STUDS – 3.7L V6 (2xHEADS) – 8740

$329.44

ARP’s Undercut Head Studs are manufactured from premium 8740 chrome moly steel and heat treated to 190,000 psi. These studs are thread rolled after the heat treating process, which vastly improves their fatigue tolerance. Undercutting of the stud equalizes the “stretch”, which makes for a more consistent clamping force; and one that compensates for head gasket compression when the cylinder heads are installed. This helps prevent blown head gaskets, and assures optimum engine sealing. Included are 12-point nuts and parallel ground washers. Also available are Undercut Head Studs With Hex Nuts.

ARP Pro Series cylinder head studs are cold-forged to ensure molecular integrity. They’re heat-treated prior to thread rolling and machining. ARP Pro Series kits are also available with 12-point nuts, and all studs come complete with hardened parallel washers for an even load distribution and accurate torque readings. With hundreds of models ready to ship, these cylinder head fasteners can be ordered for virtually any style engine.

| MAKE | MODEL | YEAR |

|---|---|---|

| MAKE | MODEL | YEAR |

| DODGE | DAKOTA | 2004 - 2011 |

| DODGE | DURANGO | 2004 - 2009 |

| DODGE | RAM 1500 | 2002 - 2008 |

| DODGE | RAM 1500 | 2009 - 2012 |

| JEEP | COMMANDER | 2005 (XK) |

| JEEP | COMMANDER | 2006 (XK) |

| JEEP | COMMANDER | 2007 (XK) |

| JEEP | COMMANDER | 2008 (XK) |

| JEEP | COMMANDER | 2009 (XK) |

| JEEP | COMMANDER | 2010 (XK) |

| JEEP | GRAND CHEROKEE | 2005 (WK) |

| JEEP | GRAND CHEROKEE | 2006 (WK) |

| JEEP | GRAND CHEROKEE | 2007 (WK) |

| JEEP | GRAND CHEROKEE | 2008 (WK) |

| JEEP | GRAND CHEROKEE | 2009 (WK) |

| JEEP | GRAND CHEROKEE | 2010 (WK) |

| JEEP | LIBERTY | 2002 (KJ) |

| JEEP | LIBERTY | 2003 (KJ) |

| JEEP | LIBERTY | 2004 (KJ) |

| JEEP | LIBERTY | 2005 (KJ) |

| JEEP | LIBERTY | 2006 (KJ) |

| JEEP | LIBERTY | 2007 (KJ) |

| JEEP | LIBERTY | 2008 (KK) |

| JEEP | LIBERTY | 2009 (KK) |

| JEEP | LIBERTY | 2010 (KK) |

| JEEP | LIBERTY | 2011 (KK) |

| JEEP | LIBERTY | 2012 (KK) |

You May Also Like:

Related products

-

AIR RAM PERFORMANCE PRODUCTS

4.7L THROTTLE BODY ADAPTER KIT (99-07 4.7L) CONVERSION to (08-UP INTAKE MANIFOLD) TBA001

$299.95Original price was: $299.95.$285.95Current price is: $285.95. Add to cart -

ENGINES AND COMPONENTS

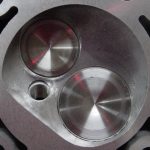

ROSS RACING PISTONS – 4.7L (USE W/SCAT RODS)

$1,195.05 – $1,554.05 Select options -

AIR RAM PERFORMANCE PRODUCTS

4.7L ESSW – Throttle Body Plenum Adapter – Aluminum – Low Profile Elbow

$461.55 Add to cart